Background:

The 2018 Merrimack Valley, MA incident (https://www.wbur.org/news/2019/10/24/federal-report-merrimack-valley-gas-explosions) and the subsequent investigations compelled Massachusetts Governor to mandate specific requirements, and the American Gas Association to recommend industry wide Pipeline Safety Management System guidelines. Before the MV incident, Eversource was already in the process of developing and implement API-RP-1173 but, recognized the value in accelerating these efforts considering the MV incident. RMG was brought in by the Executive Team to support their efforts to meet MA requirements.

Project Directive:

Develop, standardize, and implement improved work processes and practices across multiple jurisdictions, in the following areas.

- Procedures for Gas Operations that provides guidance on how to prepare, approve, revise, and implement work procedures affecting the flow of gas. Intended to aid the Preparer and users in the development and implementation of safe and consistent procedures for activities that affect the flow of gas across Gas Operations.

- Procedure Writers’ Guide intended as an aid for preparing field work JSPs (Job Specific Procedures). The Writer’s Guide is intended to promote consistency with the overall format and language used.

- Gas Control System Oversight Procedure that defines the process for notifying Gas Control, and receiving authorization from Gas Control to proceed, whenever tasks that affect the operation of the gas pipeline system are being performed or tasks that will generate an alarm condition in the control room.

- Planned Work Authorization Process that integrates all the steps required to submit and authorize work that can affect the flow of gas on the system or generate alarm conditions in Gas Control, clarifying roles, responsibilities, and tasks to plan, schedule and execute work affecting the flow of gas safely, effectively, and efficiently. Specific guidance is provided to Gas Engineering, Gas Operations, Planning & Scheduling and Gas Control to implement approved JSPs and work practices.

Pipeline Construction Drawings Procedure providing guidance for establishing the following, related to construction drawings created for pipeline work performed on the system:

- A comprehensive practice for developing drawings and managing drawing changes

- A streamlined drawing review process to ensure construction crews receive a complete, high-quality product for use in the field to meet work schedules

- Minimum specific drawing notes to be used on all drawings

- Specific drawing format requirements for third party suppliers

General Procedure for Management of Change (MOC) that defines how to formally identify, evaluate, develop, and implement the steps that meet the definition for an (MOC) plan. This procedure meets the requirements as described by API-RP-1173 “Pipeline Management System Requirements”, and ASME B31.8 Managing System Integrity of Gas Pipelines.

Process Metrics were developed to support targeted goals in Planned Work Authorization and Pipeline Construction Drawings for the timely completion and review of JSPs and P.E. Stamped Construction Drawings in support of the PSMS, and to ensure compliance to regulatory requirements at the state and Federal levels. (220 CMR 101.00 MA Natural Gas Pipeline Safety Code). CSD (Construction Start Date) change metrics were included as both work practices have a direct effect on CSD attainment.

- Developed models utilizing current methods of weekly engineering project tracking

- The following metrics would be initially tracked; # Projects, # of CSD Changes, Distribution of projects with any CSD changes, Days pulled forward or pushed out due to CSD changes, # Drawings IFC, # Drawings late and % OTD of Drawings

- Metric tracking and reporting include weekly updates and base (YTD) summaries

Project Results:

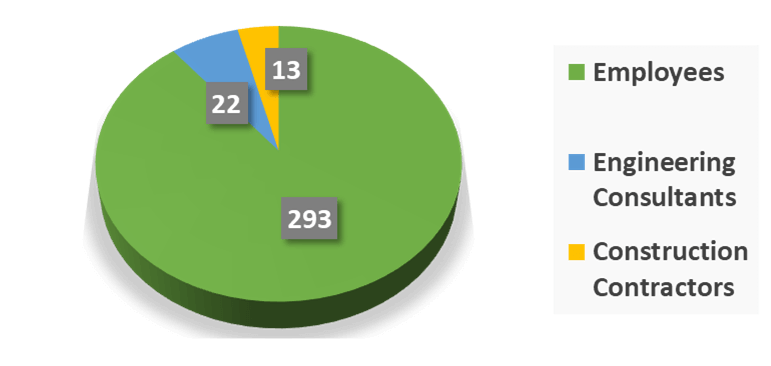

All processes and practices implemented across Gas Business. 328 individuals were trained on these processes and practices.