Background and Situation:

- Power stations in the Allegheny System represent approximately 5000 MW of generating capacity

- Significant reductions in boiler tube leaks were paramount to continued business competitiveness. More than 90% of forced outages were traced to boiler tube leaks that could have been averted by the timely completion of the right proactive outage work.

- The Assessment found:

- Poor outage scoping and disorganized work list development.

- Outage preparation timelines of six months or less.

- Critical path scheduling methodology not used.

- Daily schedules were not prepared during outages.

- Sporadic and untimely outage documentation.

- No formal tracking and review of standard key performance indicators to support problem solving and continuous improvement.

Objectives:

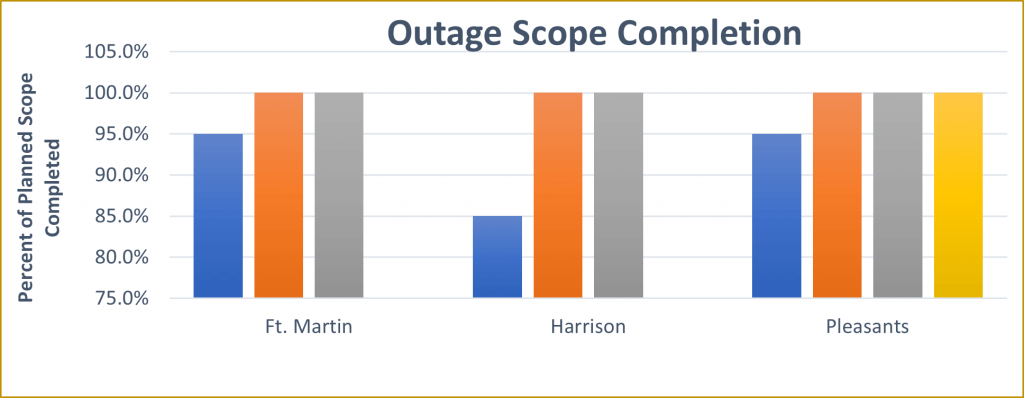

- Improve overall reliability by completing more proactive outage work. Achieve scope completion rates of more than 95%.

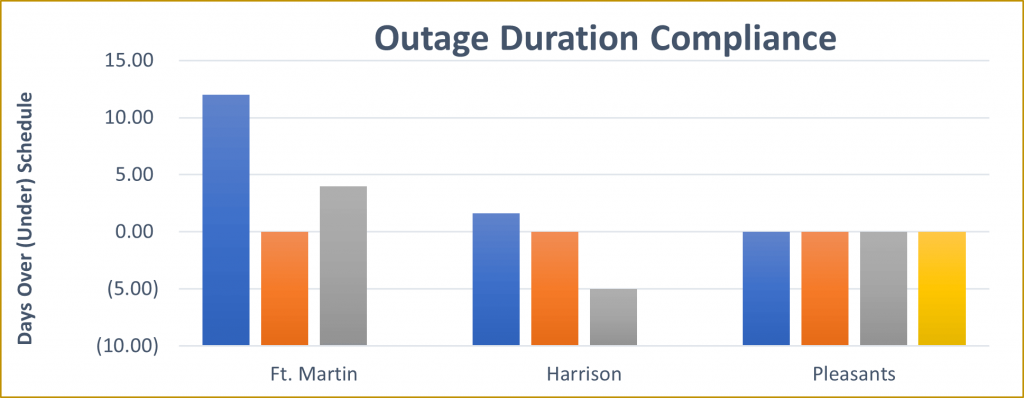

- Improve schedule compliance, finish outages by scheduled end date.

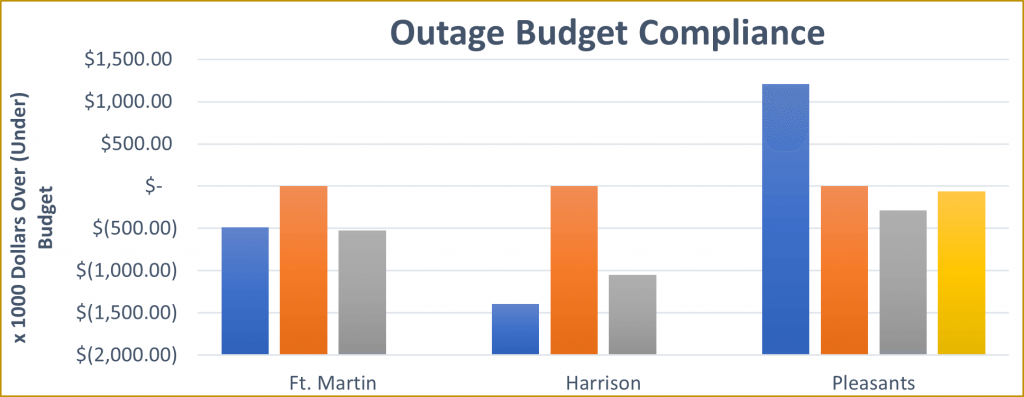

- Improve outage cost tracking and control, providing more useful information daily to station managers. Manage outage costs to outage budgets. (+/- 3% variance from budgets)

Results:

- Formal outage planning and scheduling implemented in all supercritical stations. Percent of work planned for each outage went from <20% to >90%.

- Scope completion rates went from ~85% or 90% to a consistent 98% and above.

- On average, outages were 4.1 days longer than their scheduled duration for the base period versus 0.25 days less than their scheduled duration for the ROI period. Additional revenue for duration improvements to date is estimated at $3,118,650.

- Money saved by more closely meeting budgets totaled $334,168. Outage cost tracking now uses a continuously improving set of standard reports and software that have been developed by a system-wide team.

- Outage critiques and documents are completed for every planned outage.

- Standard outage planning and tracking procedures across the system has allowed for greater resource sharing among stations. Outage performance improvements have taken place despite a 10% corporate-wide reduction in management staff.