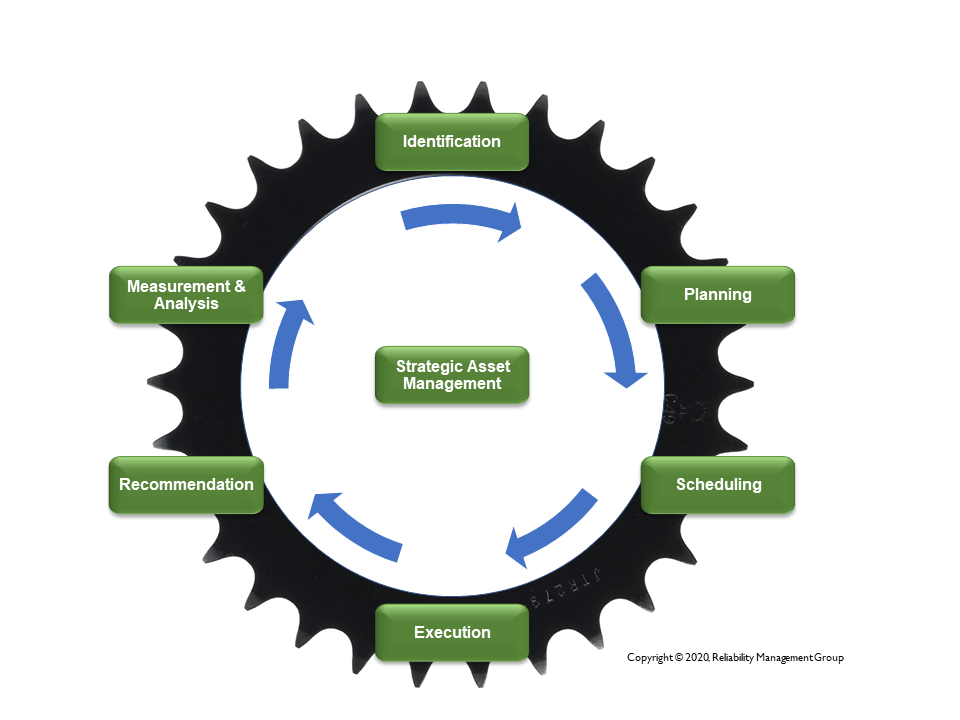

Asset Reliability Optimization

Identification

- Plant & Reliability Event(s) capture

- Opportunity impact/ value quantification

- Future risk determination

- Event correlation

- Event identification and categorization/ prioritization

- Assign analysis and response Owner

Planning

- Plan/Define scope of

- RCFA Analysis

- FMEA Analysis

- Bad Actor

- Problem Solving

- Define level of System/ /Process/Equip knowledge

- Define resource levels & skills required

- Issue justification/need for approval

Scheduling

- Role assignment

- Task assignment

- Team training & preparation

- Coordination with plant resources and activities

- Issue estimated timeline and project brief

- Confirm Ownership

Accomplishment

- Execute agreed process steps

- RCFA analysis

- FMEA analysis

- Bad Actor analysis

- Problem Solving

- Progress tracking & updates

- Data gathering and fact resolution

- Quantify Improvement/resolution

- Team completion/signoff

- Audit of results/approval

Documentation

- Performance improvement data capture

- Formal Result/Recommendation documented and issued

- Recommendation ownership

- Formal change procedure (standards, procurement, equipment, SOP, etc.)

- Ops/ Maintenance/ Eng. Work processes

- Logistics support re-alignment

- Contracts

- Inventory

- Skill requirements

- Maintenance plans

- Ops Procedures

Analysis & Measurement

- Improvement tracking/ Value reporting

- Objective non-fulfillment escalation

- System/ Equipment functional analysis (RCM)

- Performance trending/gap analysis

- Recommendation tracking and reporting